Self-Propelling Carriage: Applied Materials Exploration

Challenge

Create an assembly that takes advantage of innate material properties of additive manufacturing materials in a functional manner.

Action

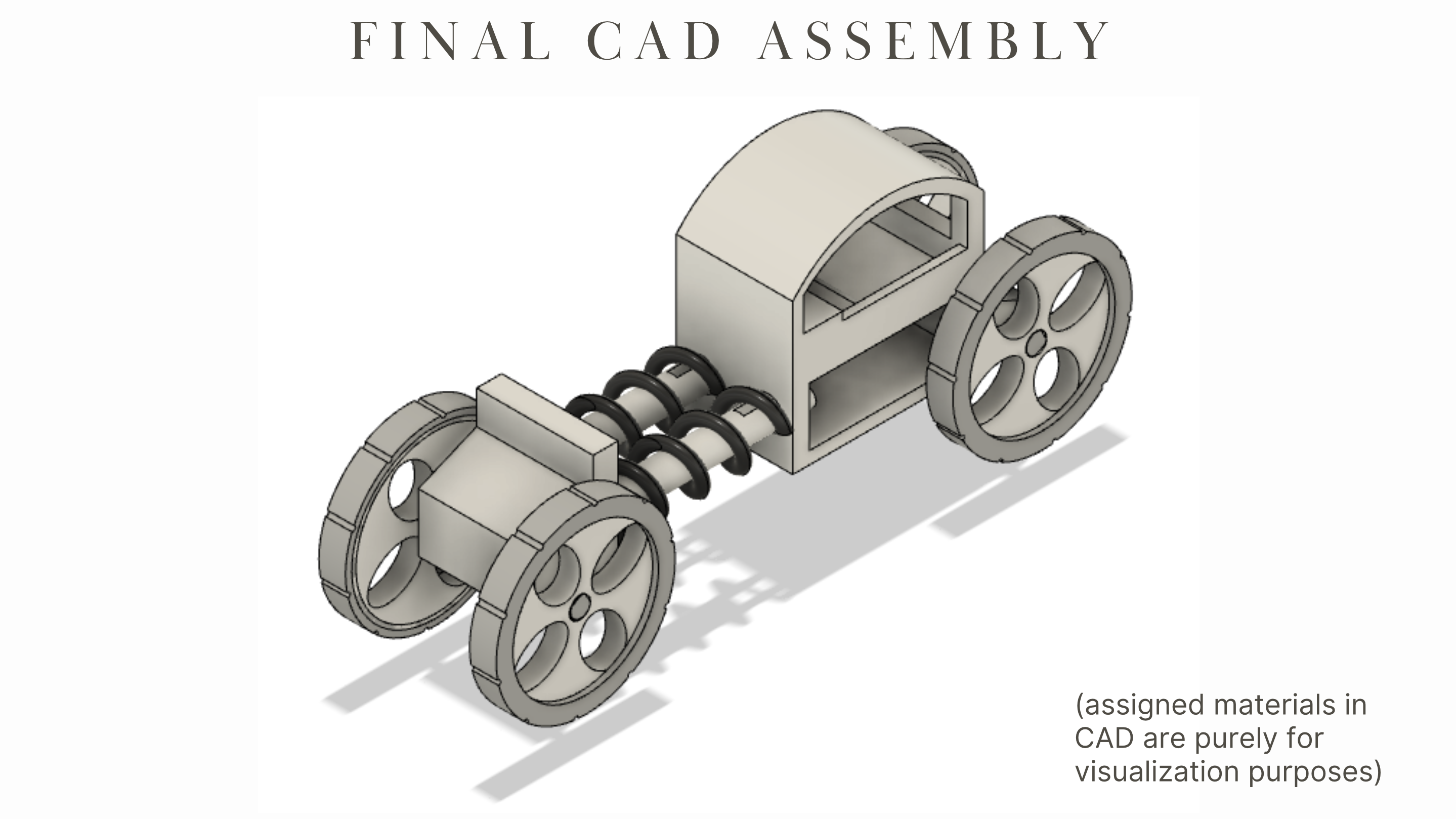

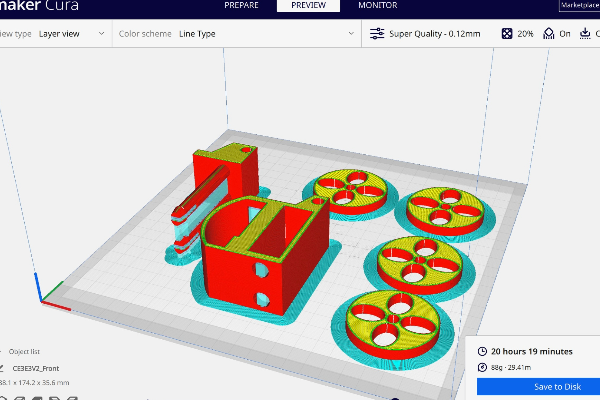

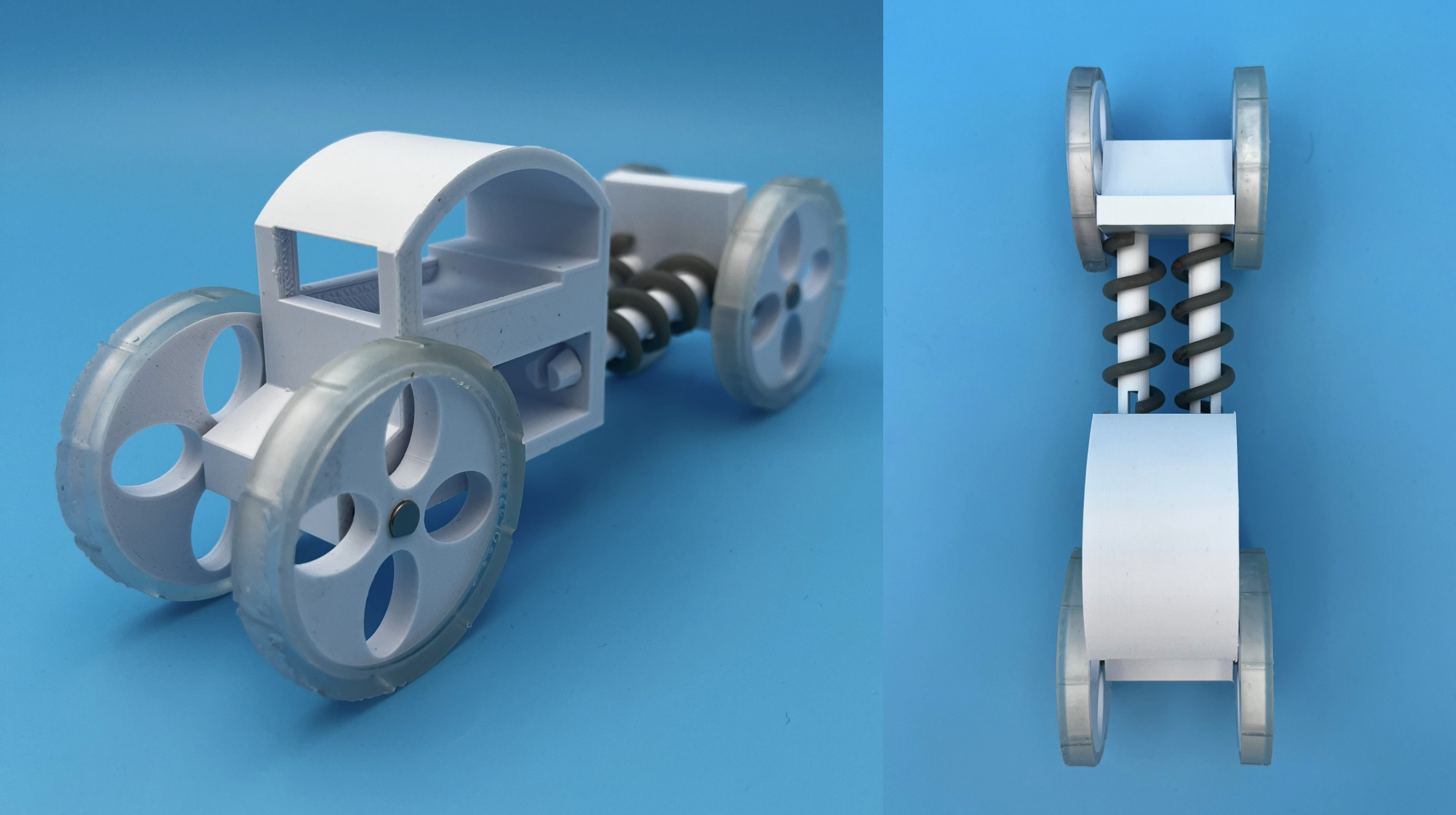

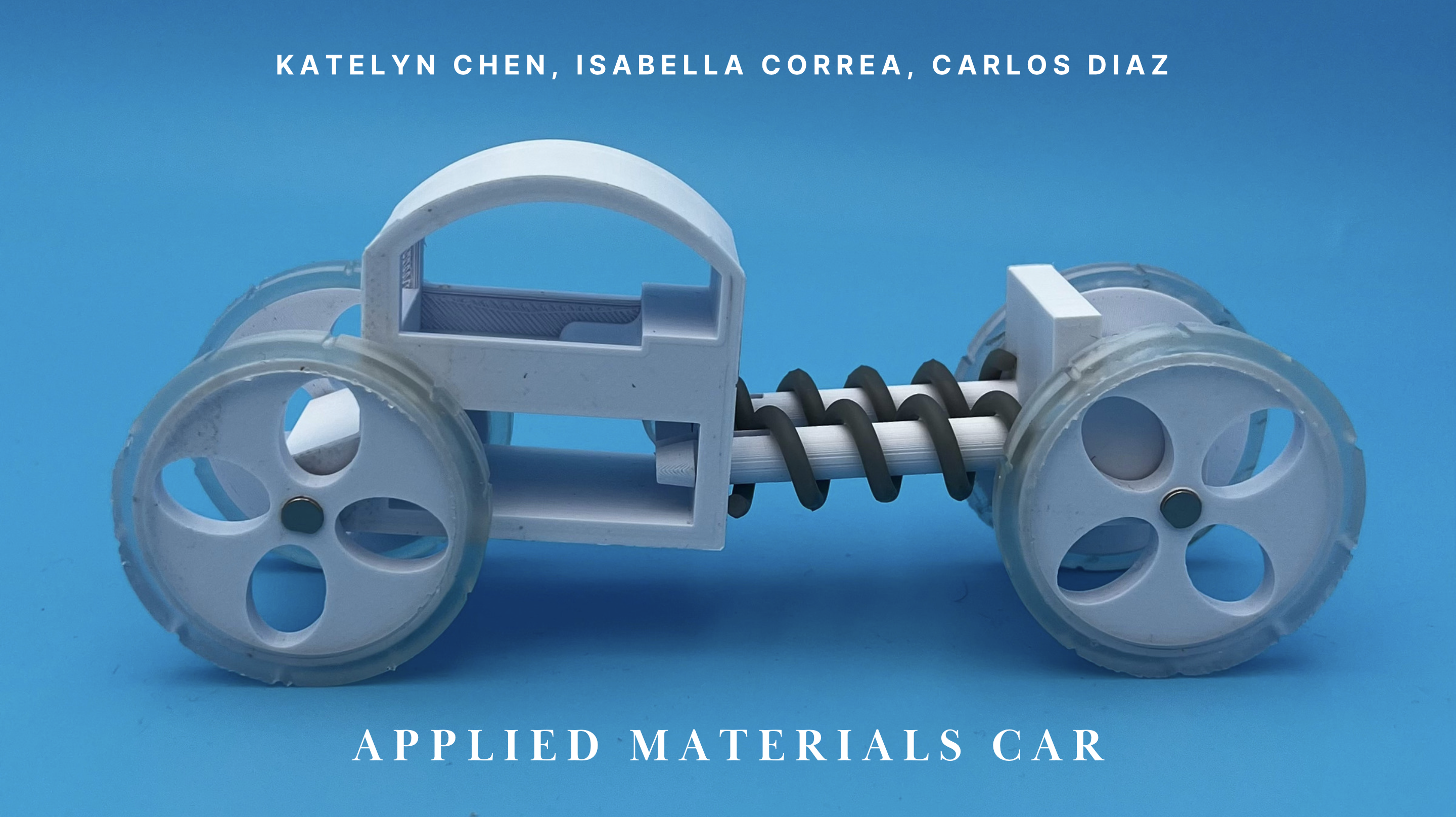

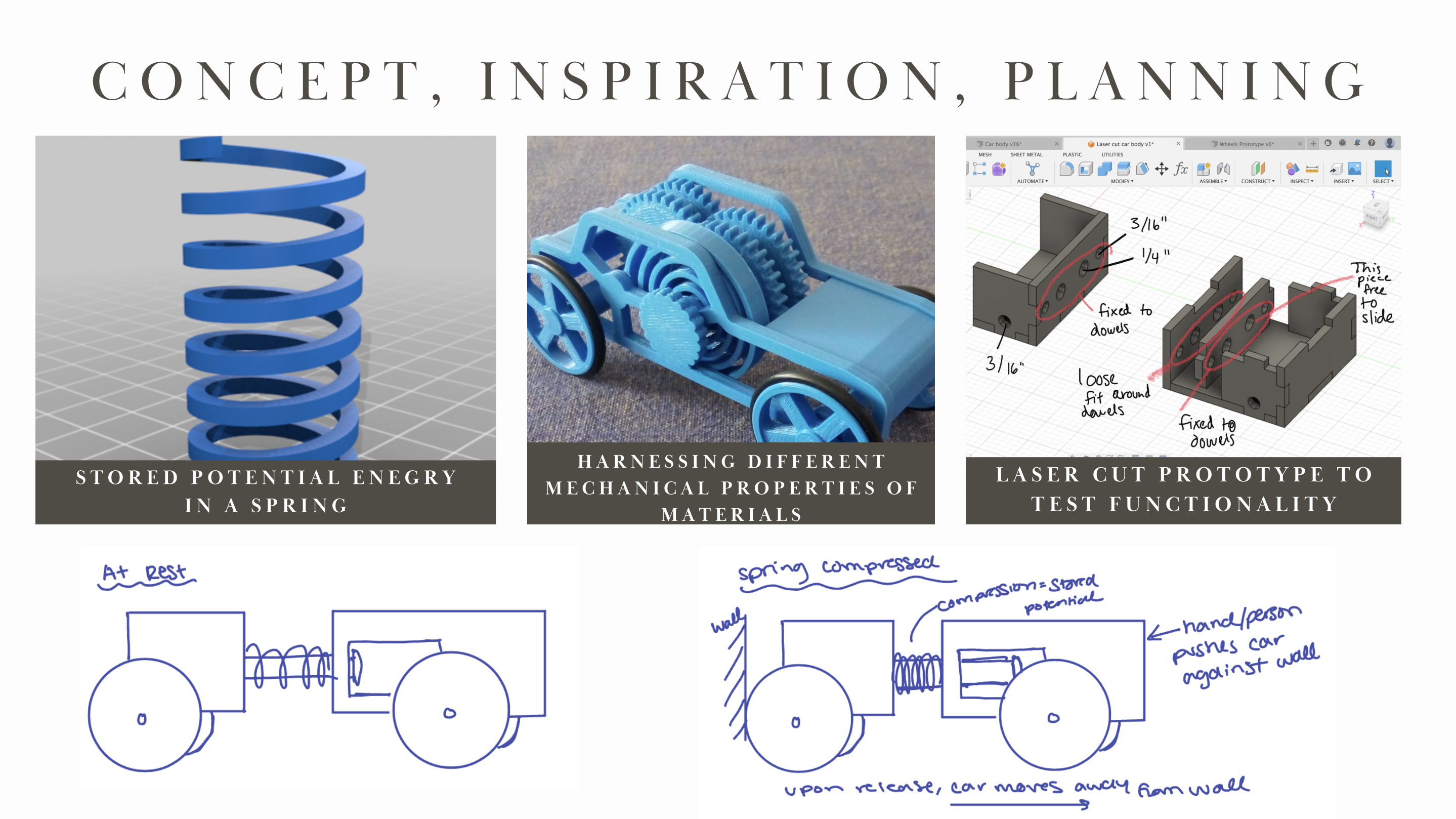

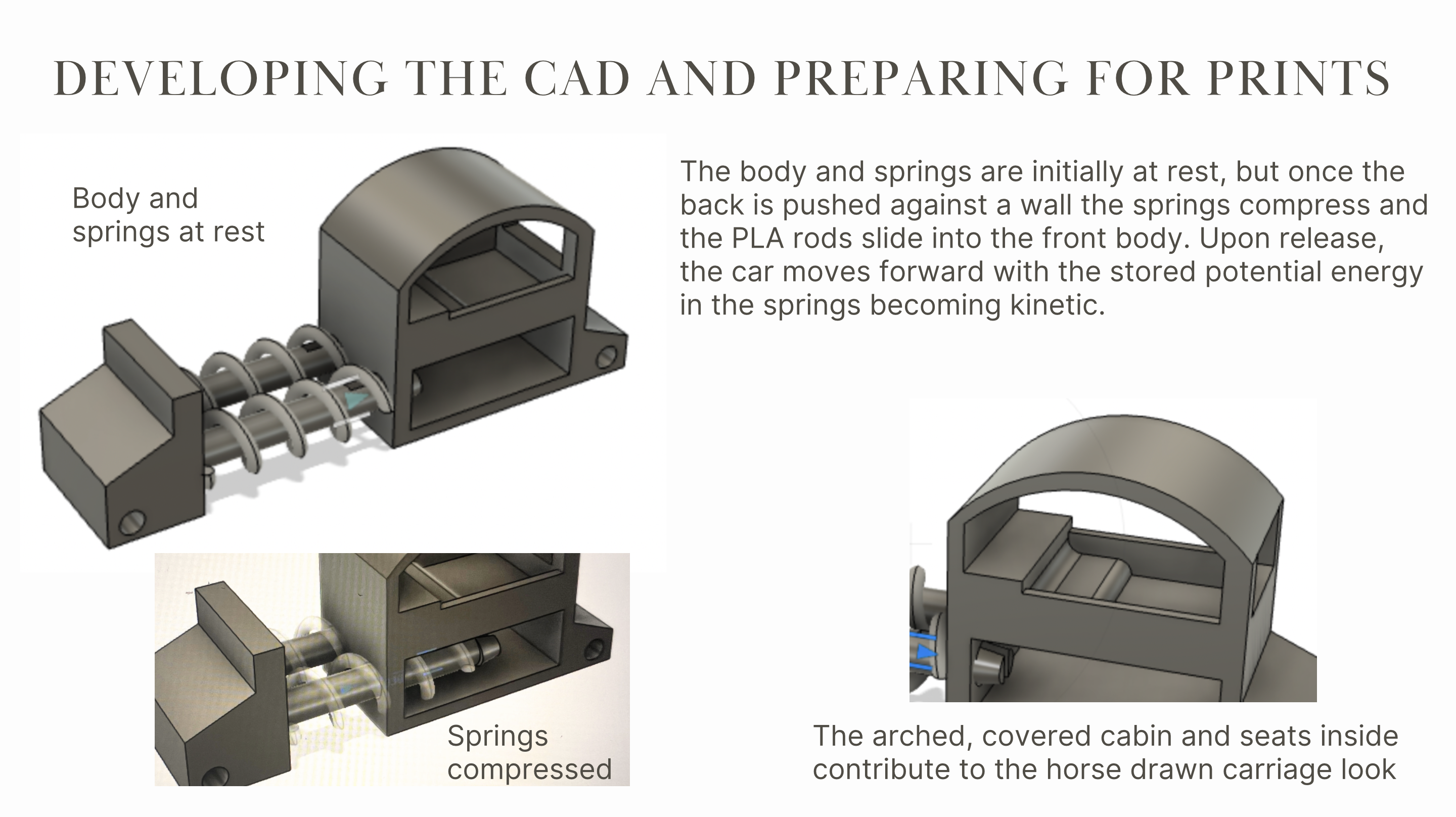

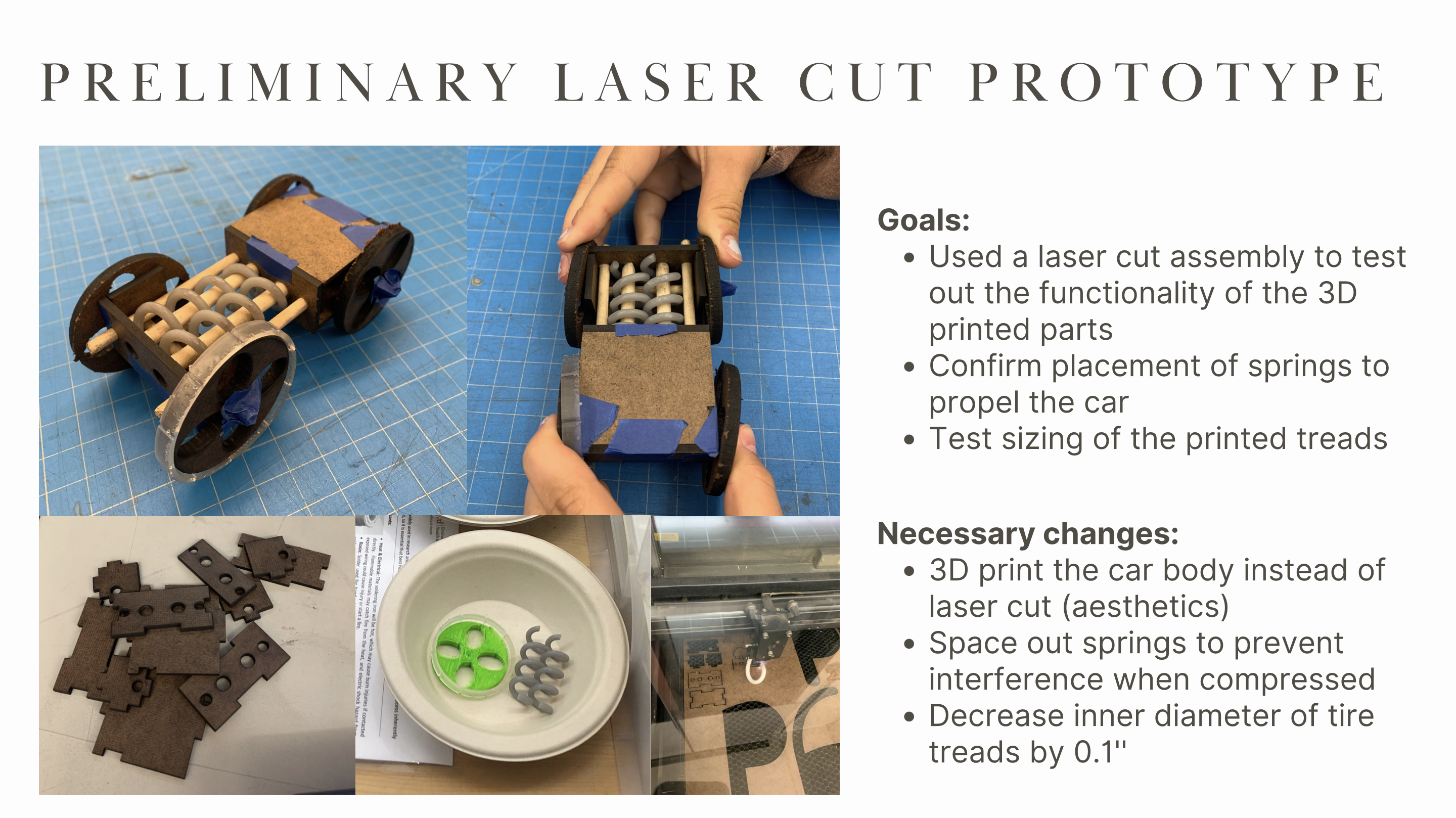

- In a team of three, we designed a spring-powered car that was fully 3D printed.

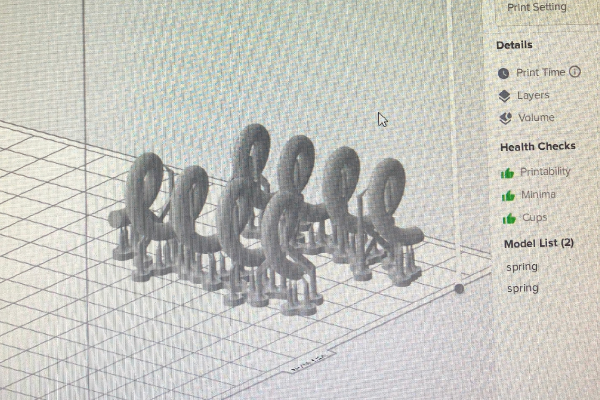

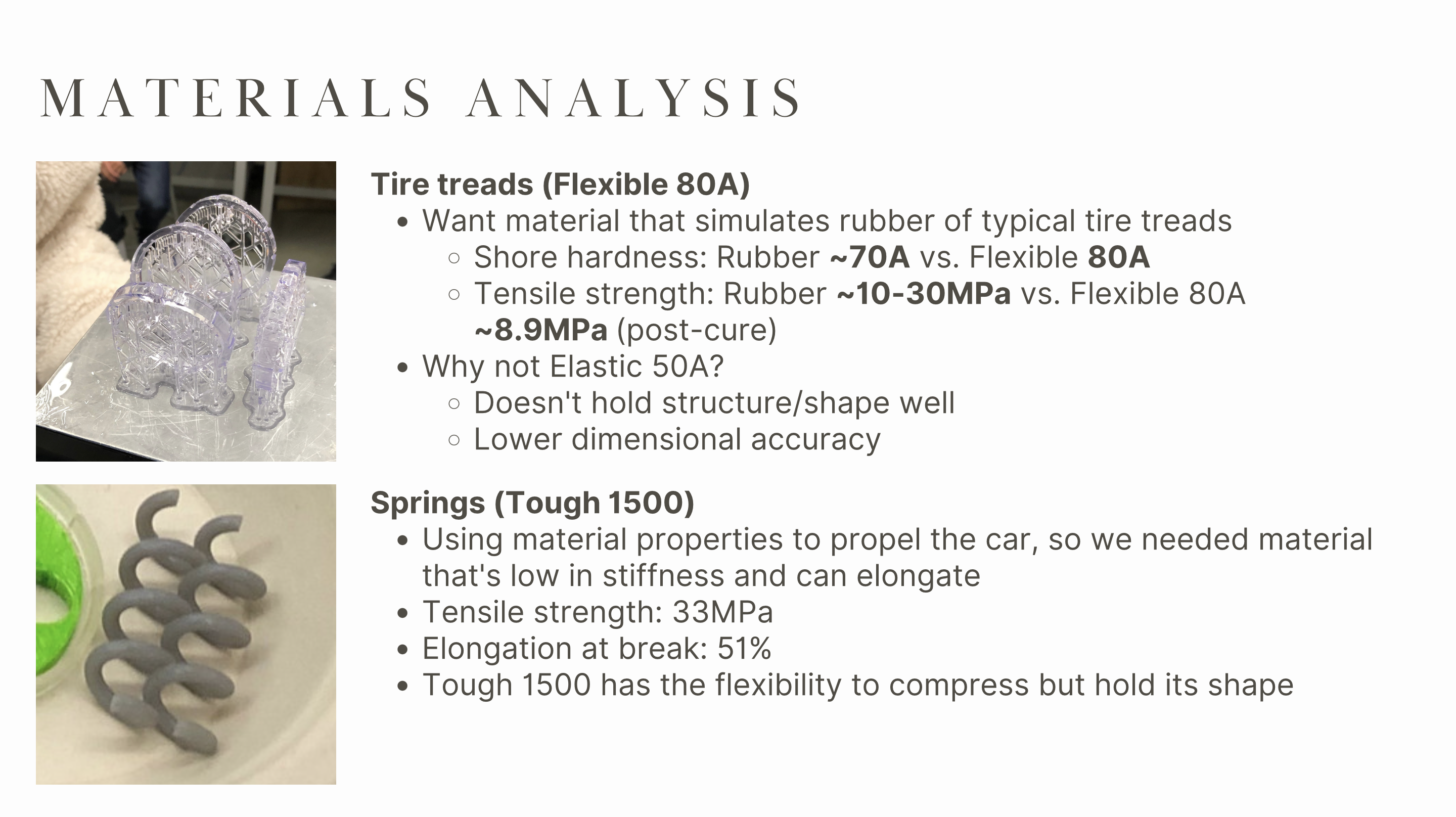

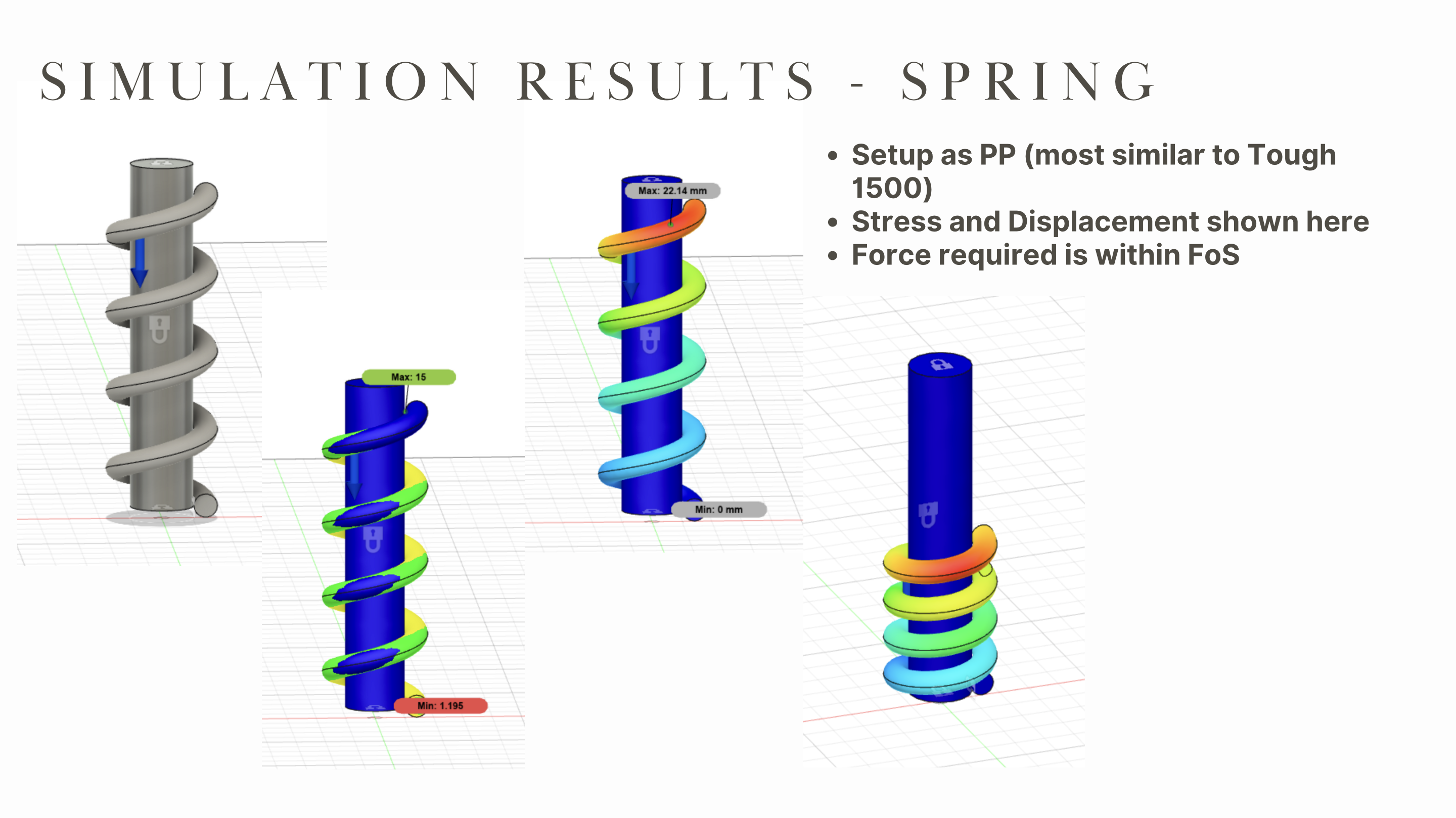

- The springs were printed out of Tough 1500 for its ability to spring back after compression.

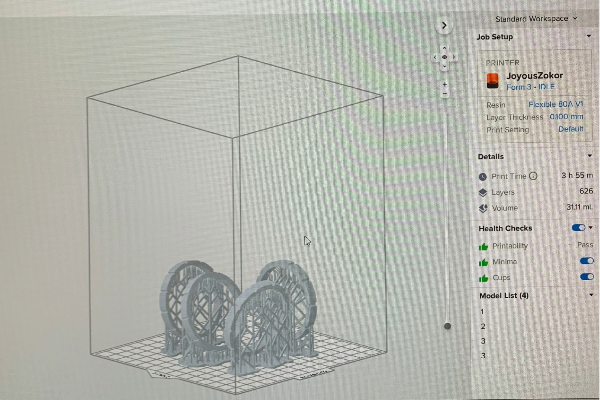

- The tire treads were printed out of Flexible 80A to best simulate rubber while not causing too much friction.

Result

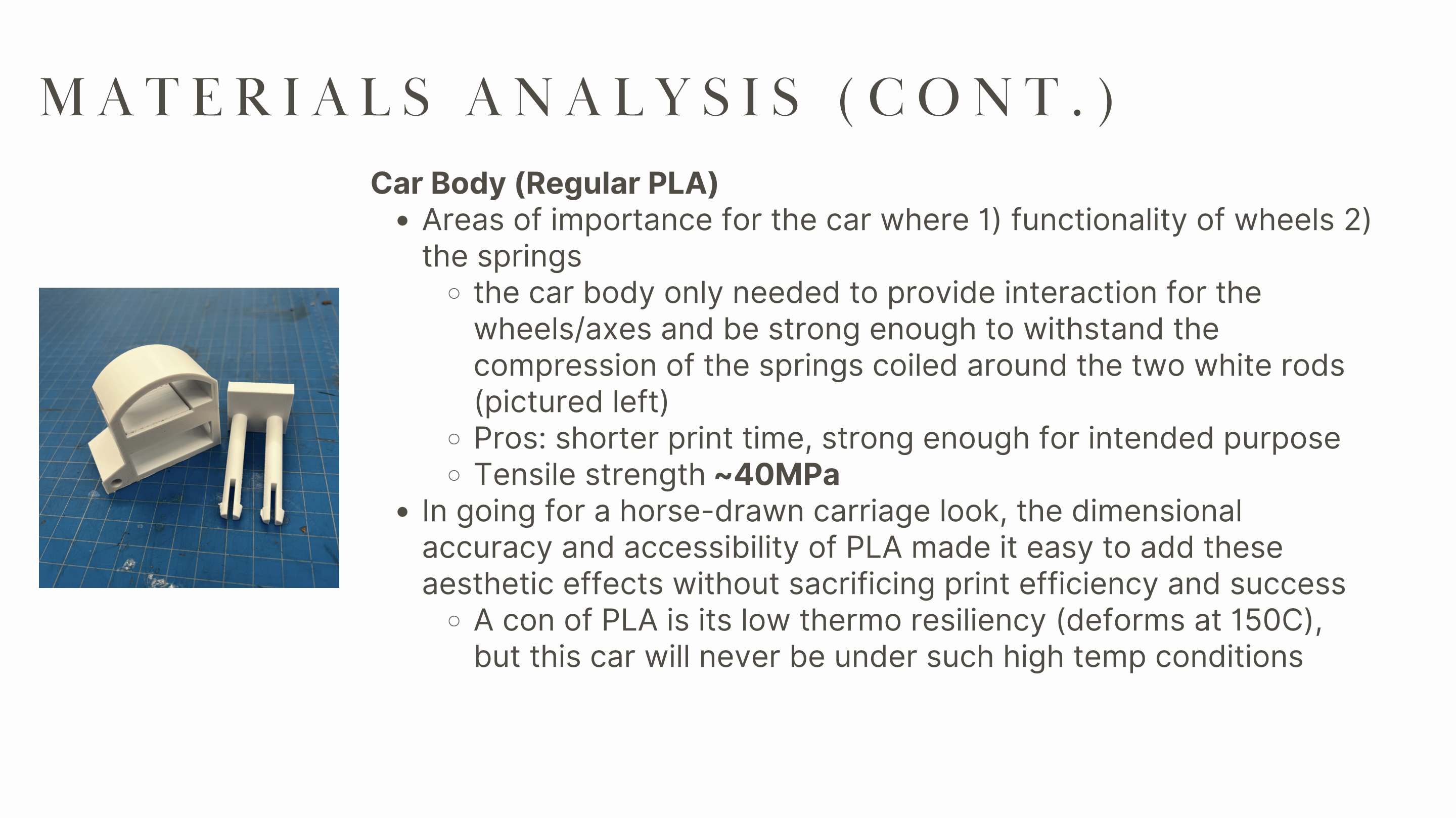

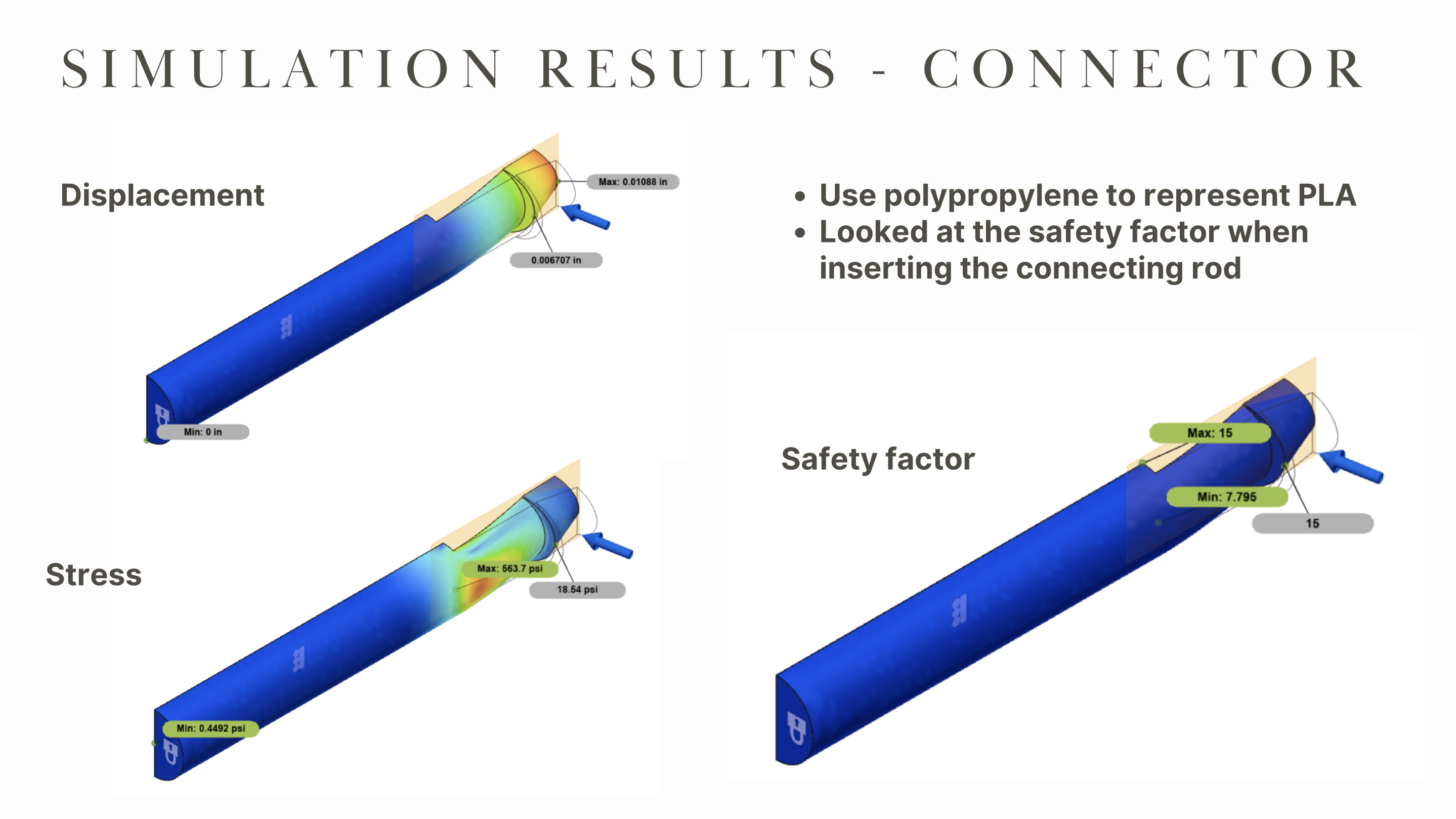

- The final product consisted of PLA car bodies and tires, snap fit connectors between the two bodies, Tough 1500 springs, and Flexible 80A treads.

- The back can be pushed against a wall and let go to make the car run. & Through this project, I learned to analyze material properties and understand how to incorporate them into designs as functional parts.