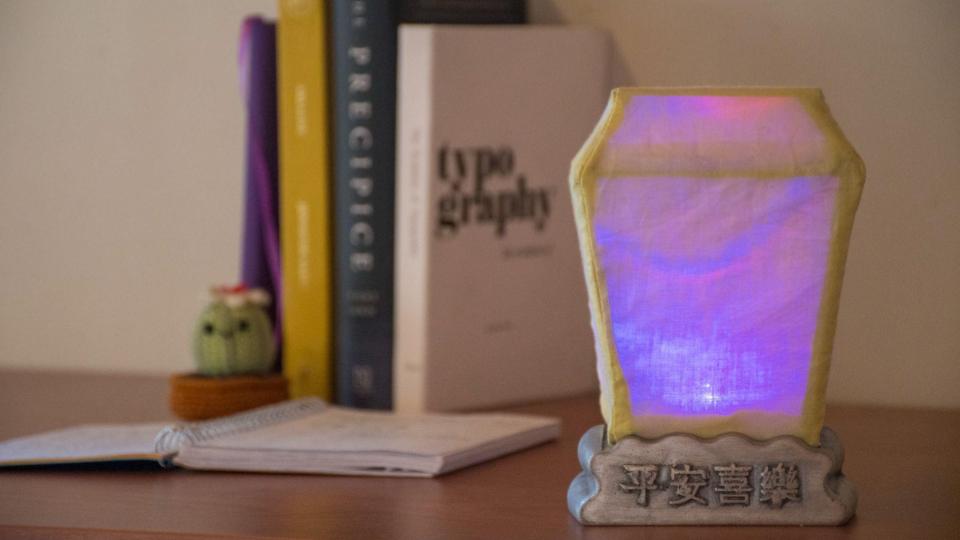

Taiwanese Sky Lantern

I designed and created from scratch a Taiwanese sky lantern inspired night light. I learned and executed machine shop skills such as machining, woodworking, welding, and sandcasting.

Sand Casting

- I used Fusion 360 to design my pattern and iterated to compromise between draft angle, functionality, and aesthetics in CAD.

- The pattern was 3D printed in PLA in two parts with integrated fixturing holes on the base.

- The patternboard was created from scratch according to the size of the cope and drag.

Machining (Mill)

- Steel tubes (0.375” OD, 0.065” wall thickness) were fishmouthed at 8.6º and 28.6º to form the frame of the lamp

- The sand cast base was machined to form the shallow recess for the lamp to sit in

Welding

- 20 steel tubes were welded together using TiG welding with mild steel as the filler material.