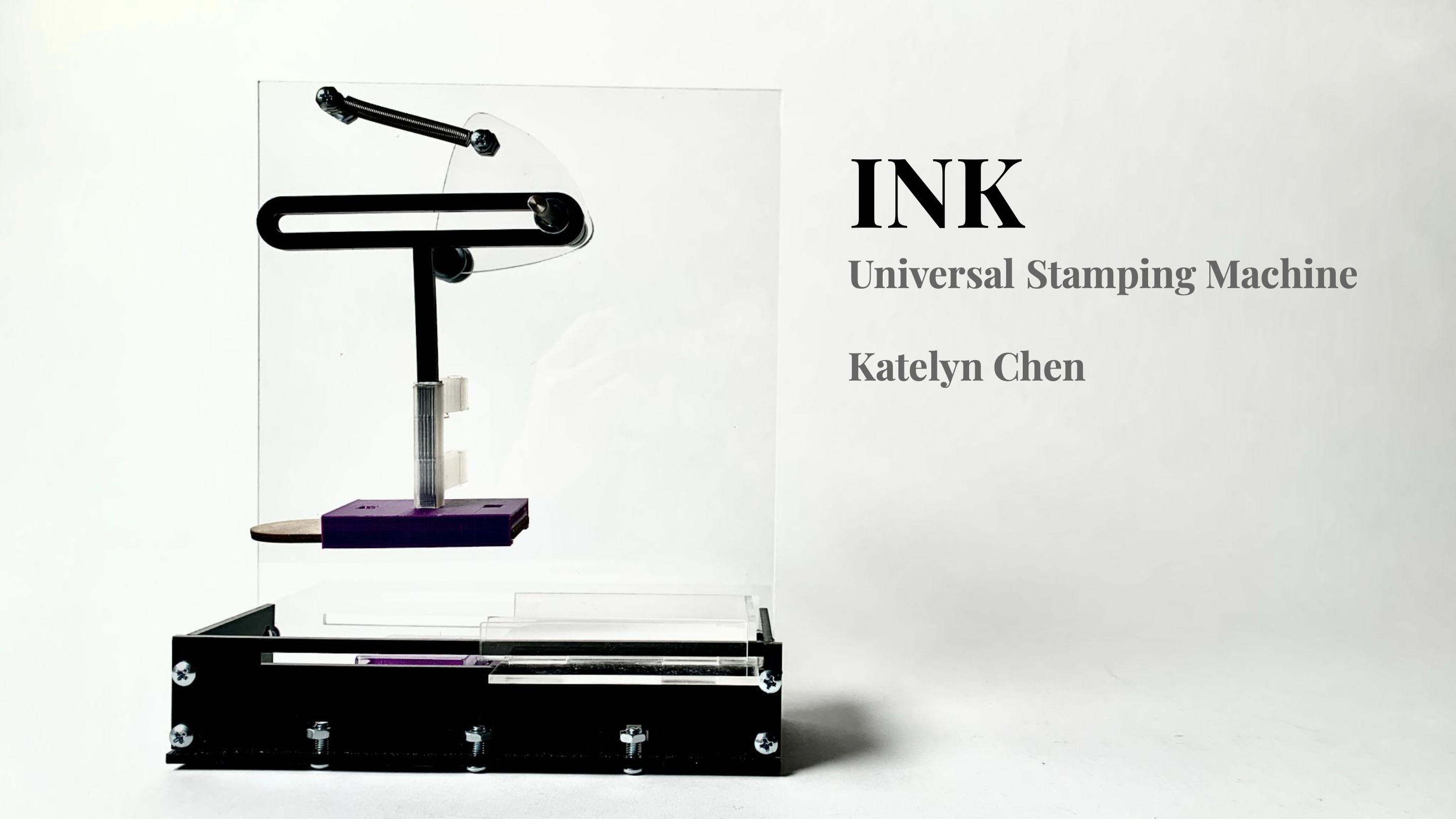

INK: The Universal Stamping Machine

Challenge

- Manually operated stamping machines face difficulties in its required force, precision, and universality.

- These machines need to produce consistent results with high precision while requiring low force for increased accessibility.

- I aimed to create a machine that operates using rotary motion and resets itself each time. All parts must be connected and approximately within 10’’ x 8’’ x 4’’.

Action

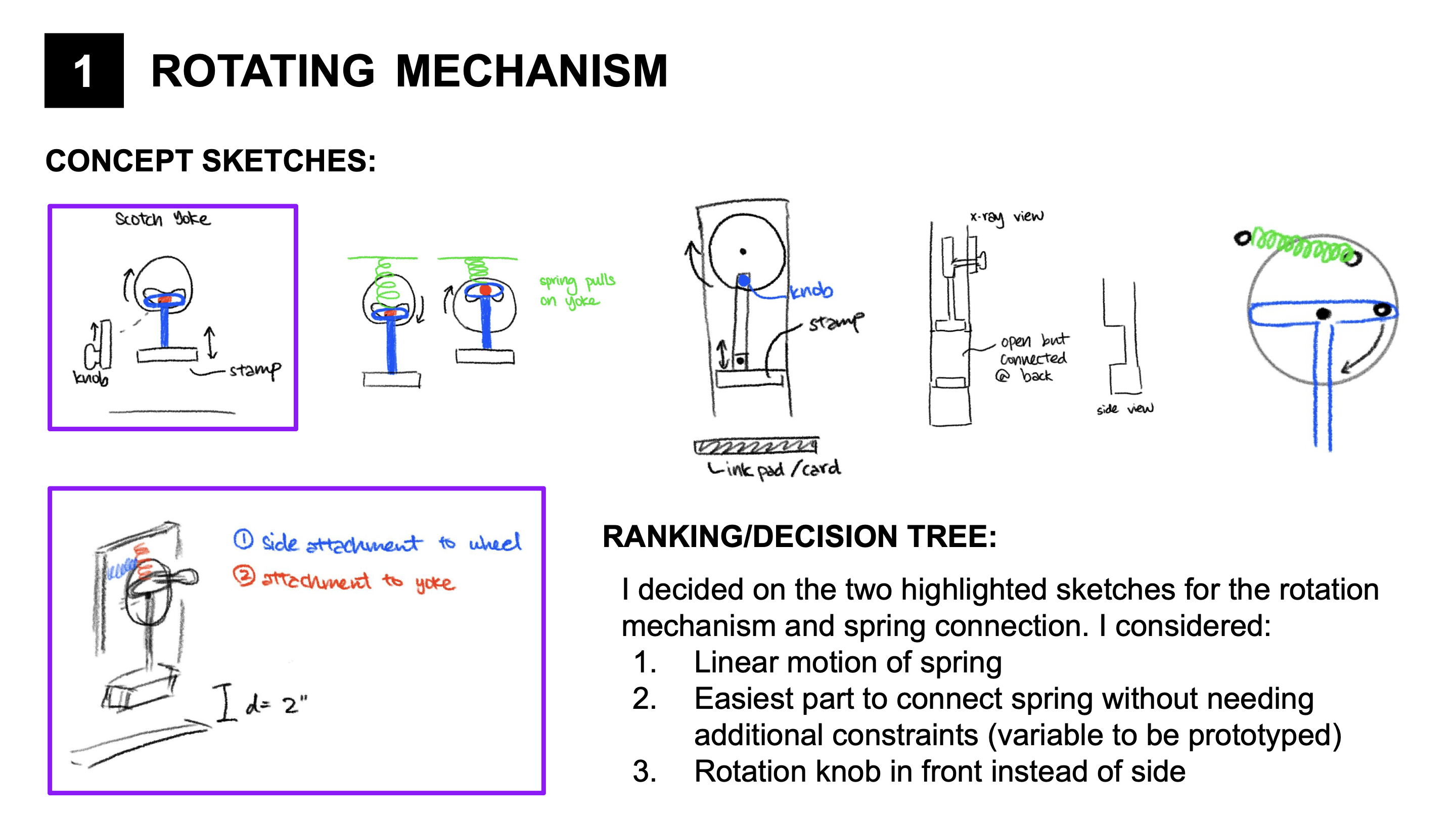

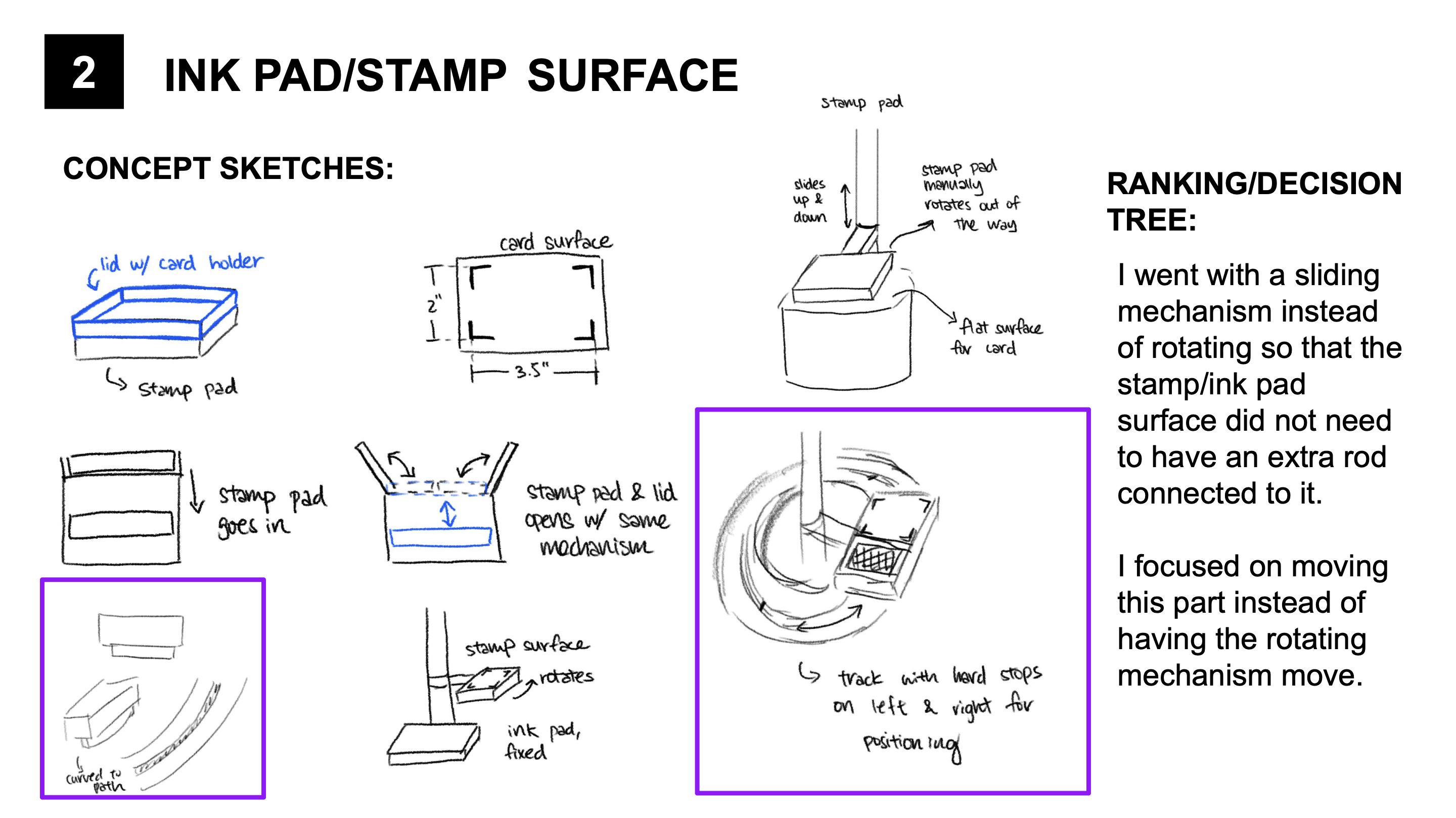

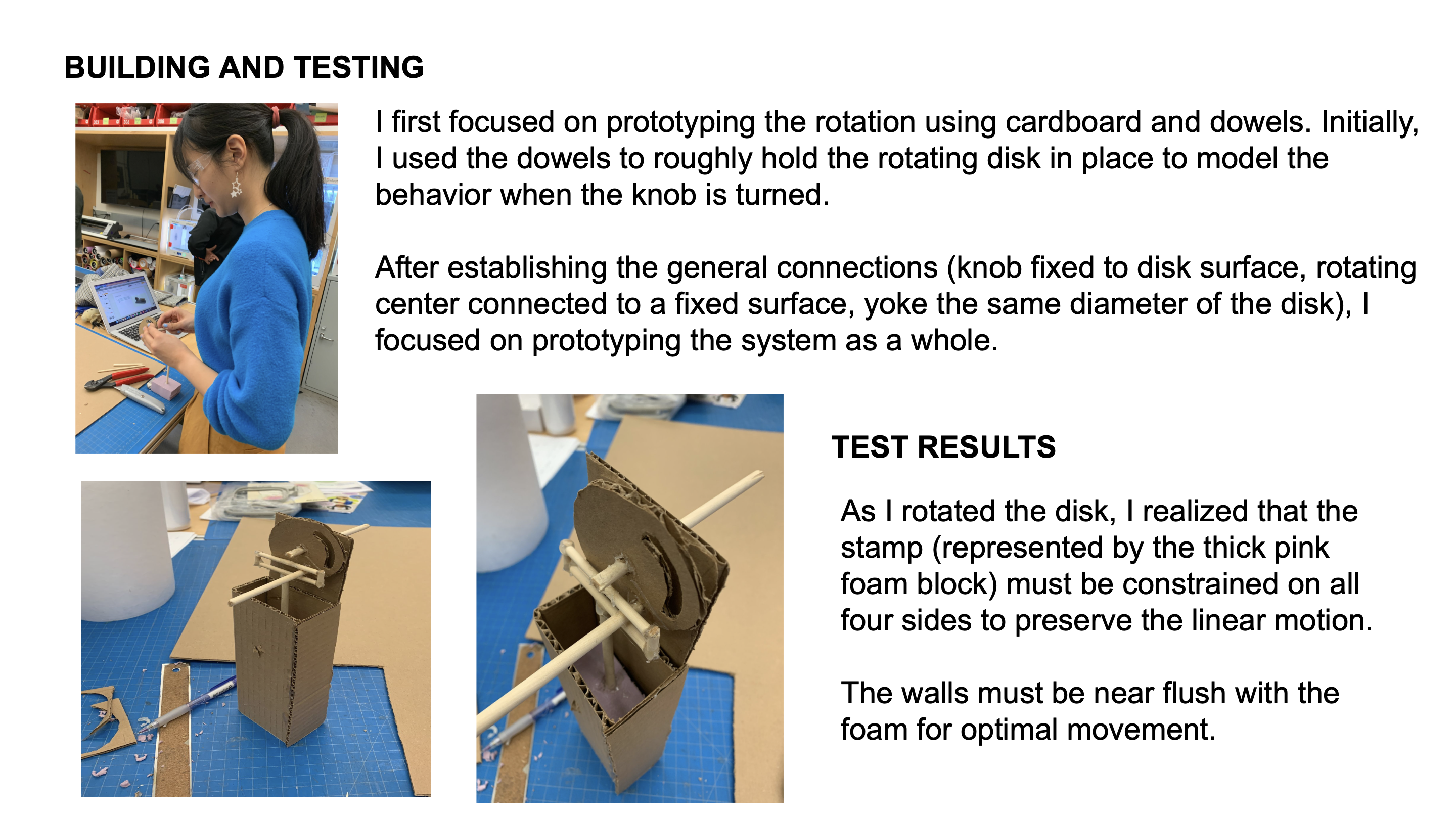

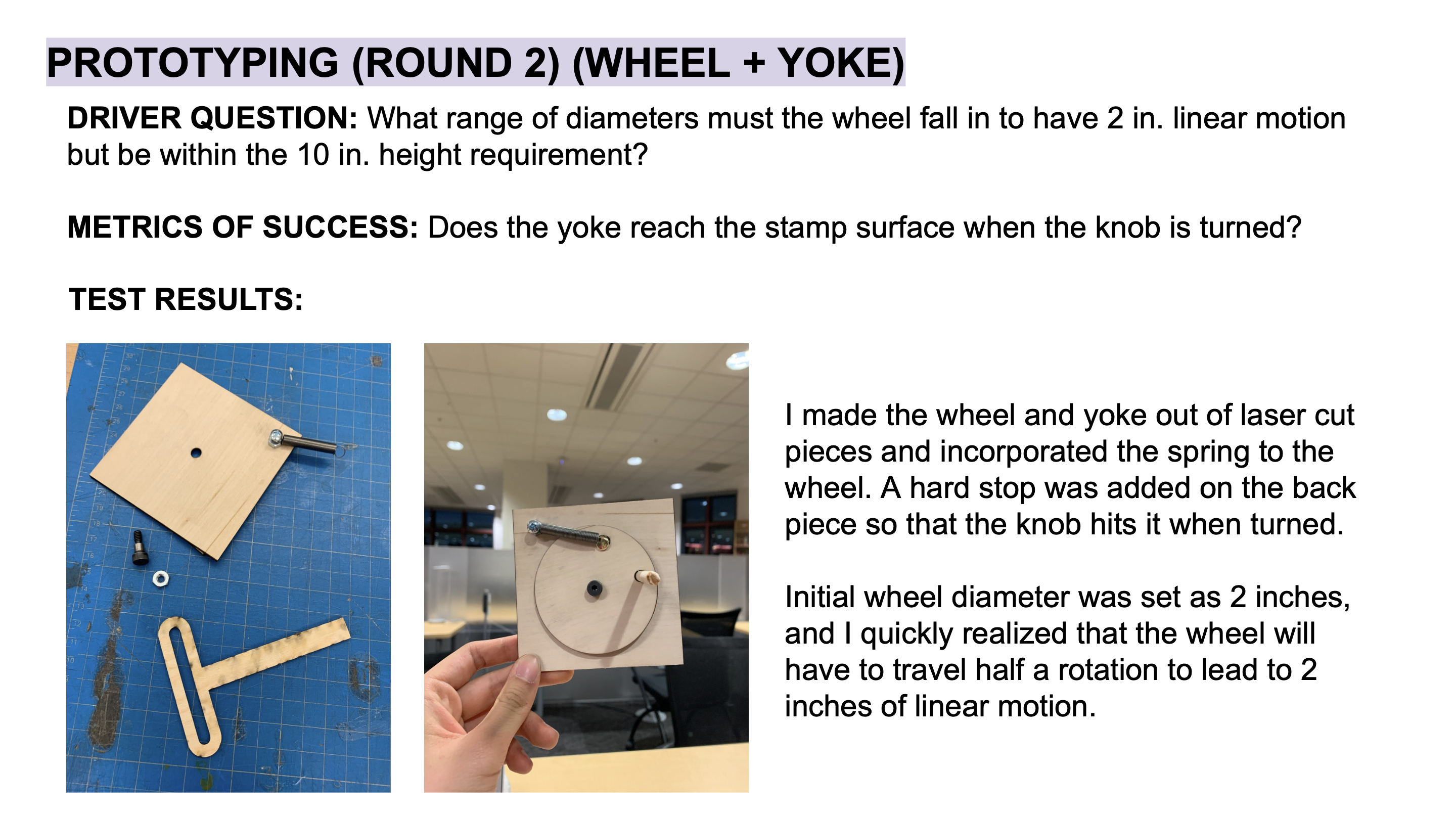

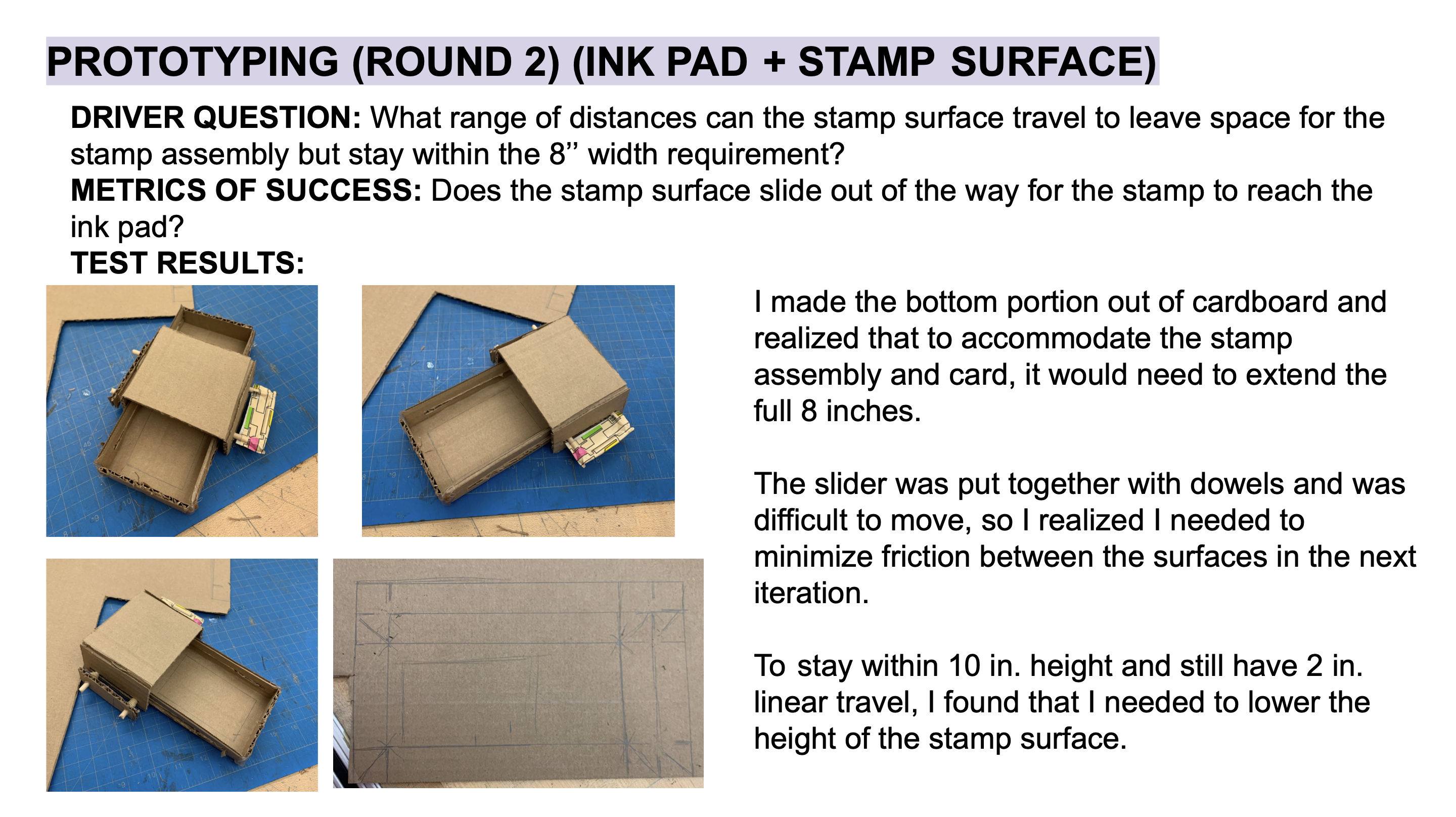

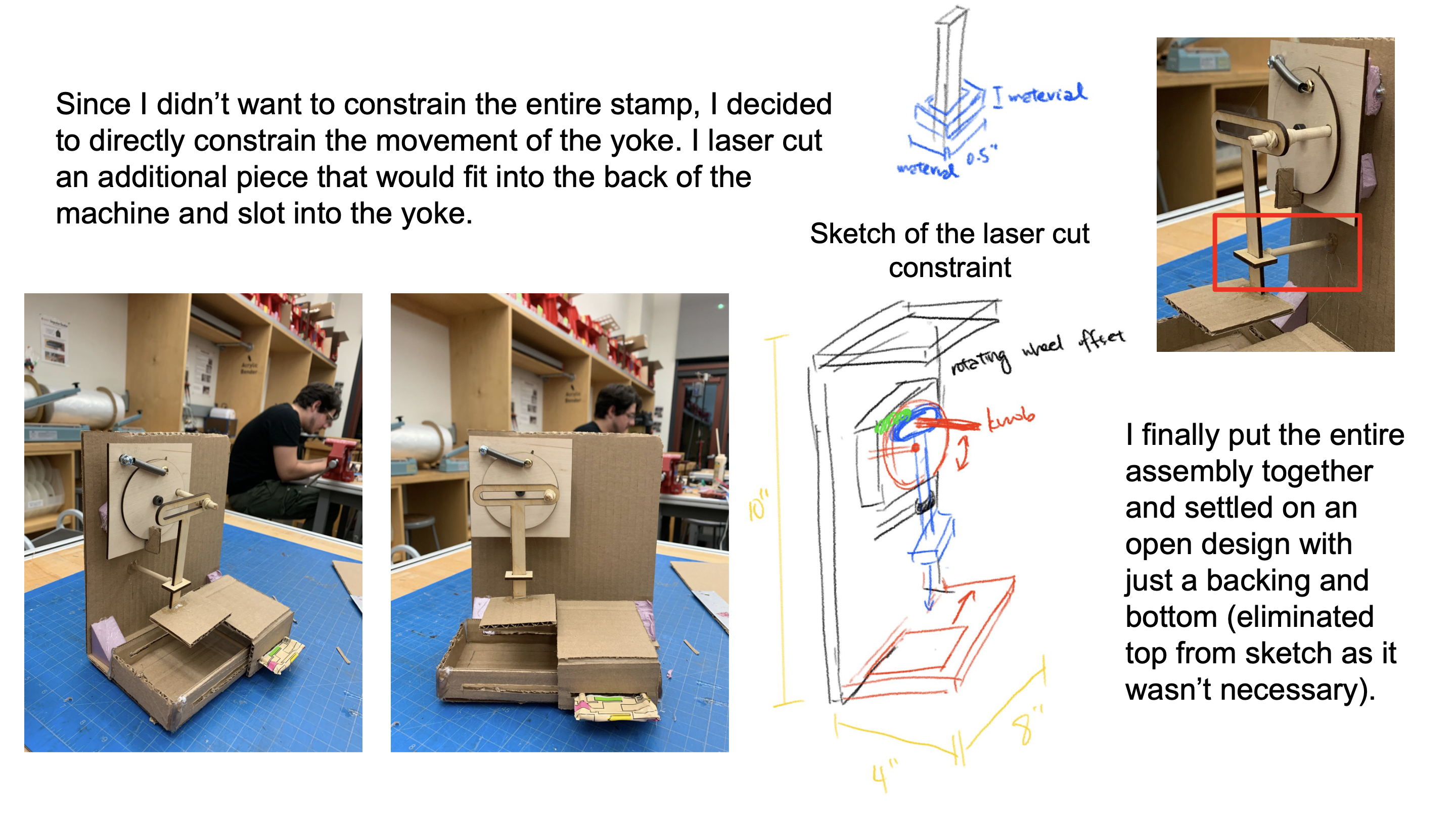

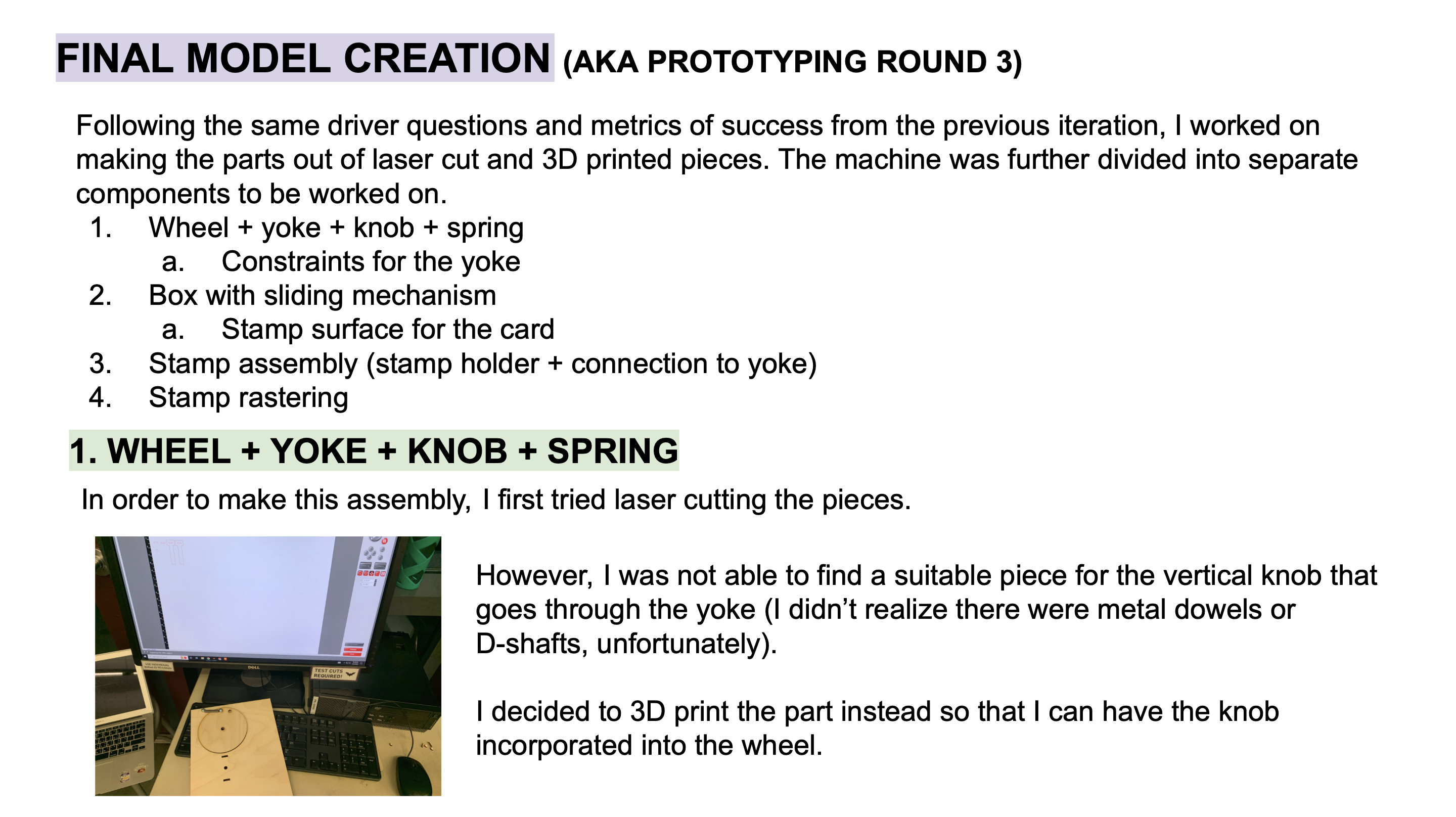

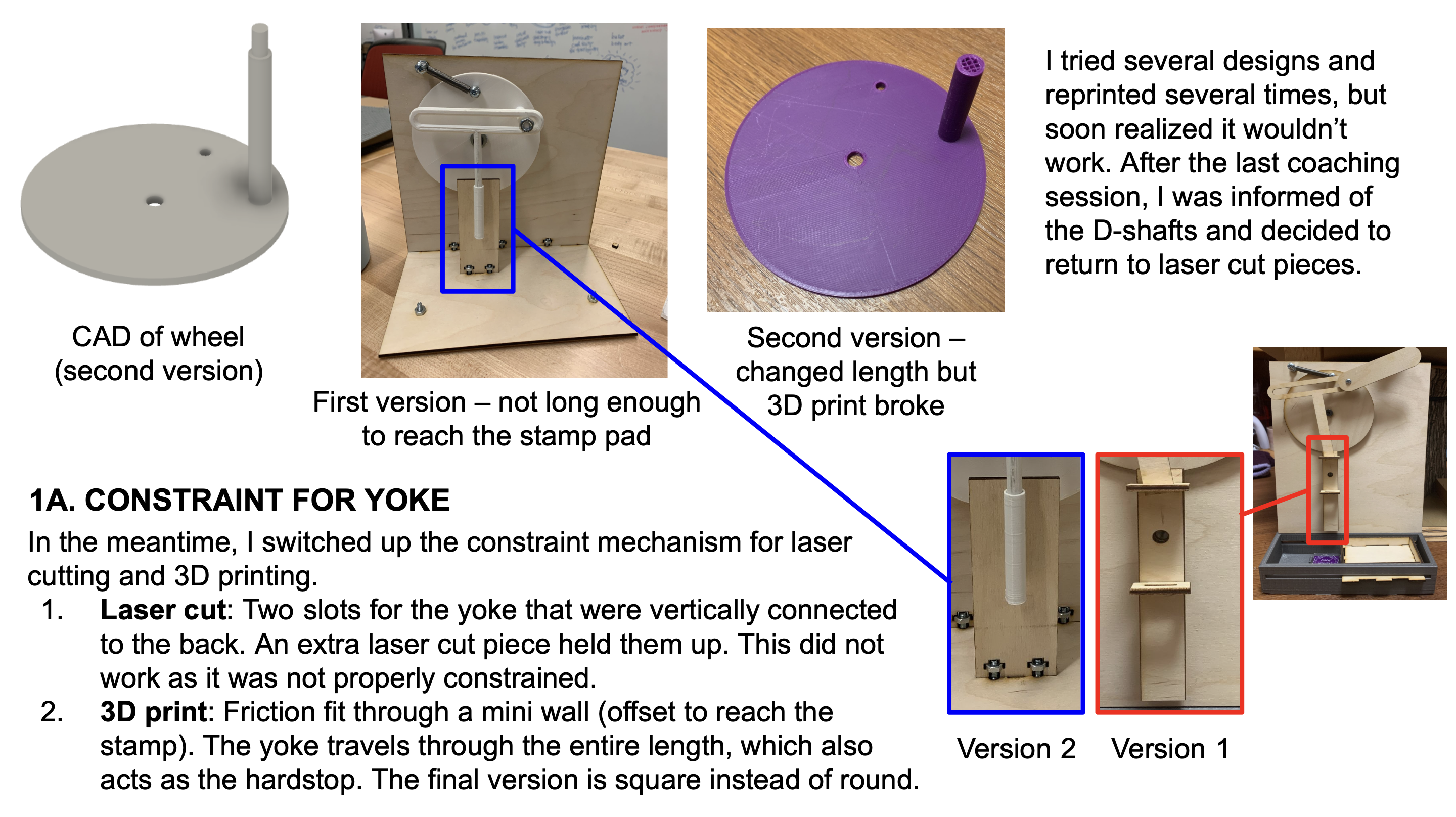

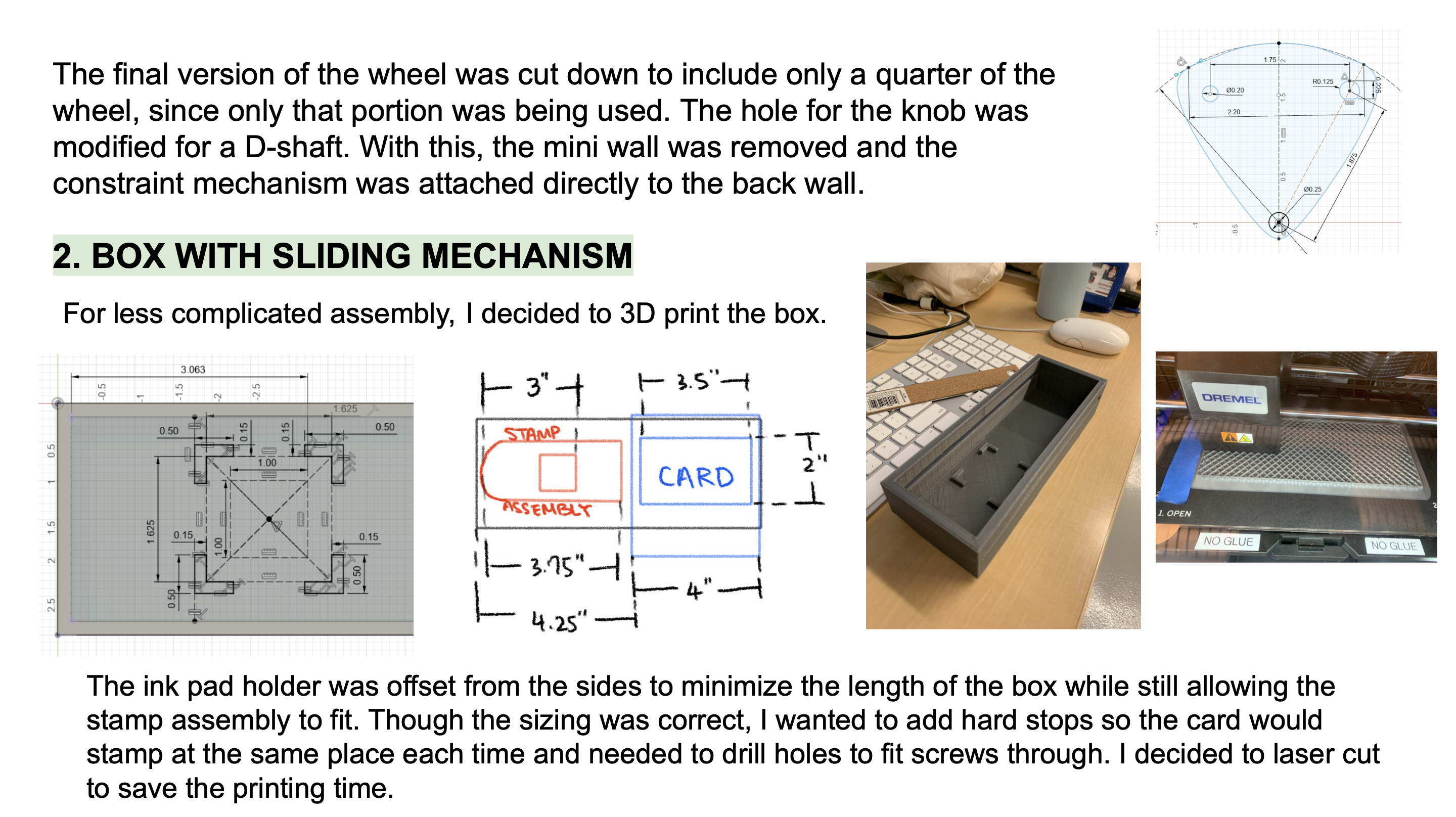

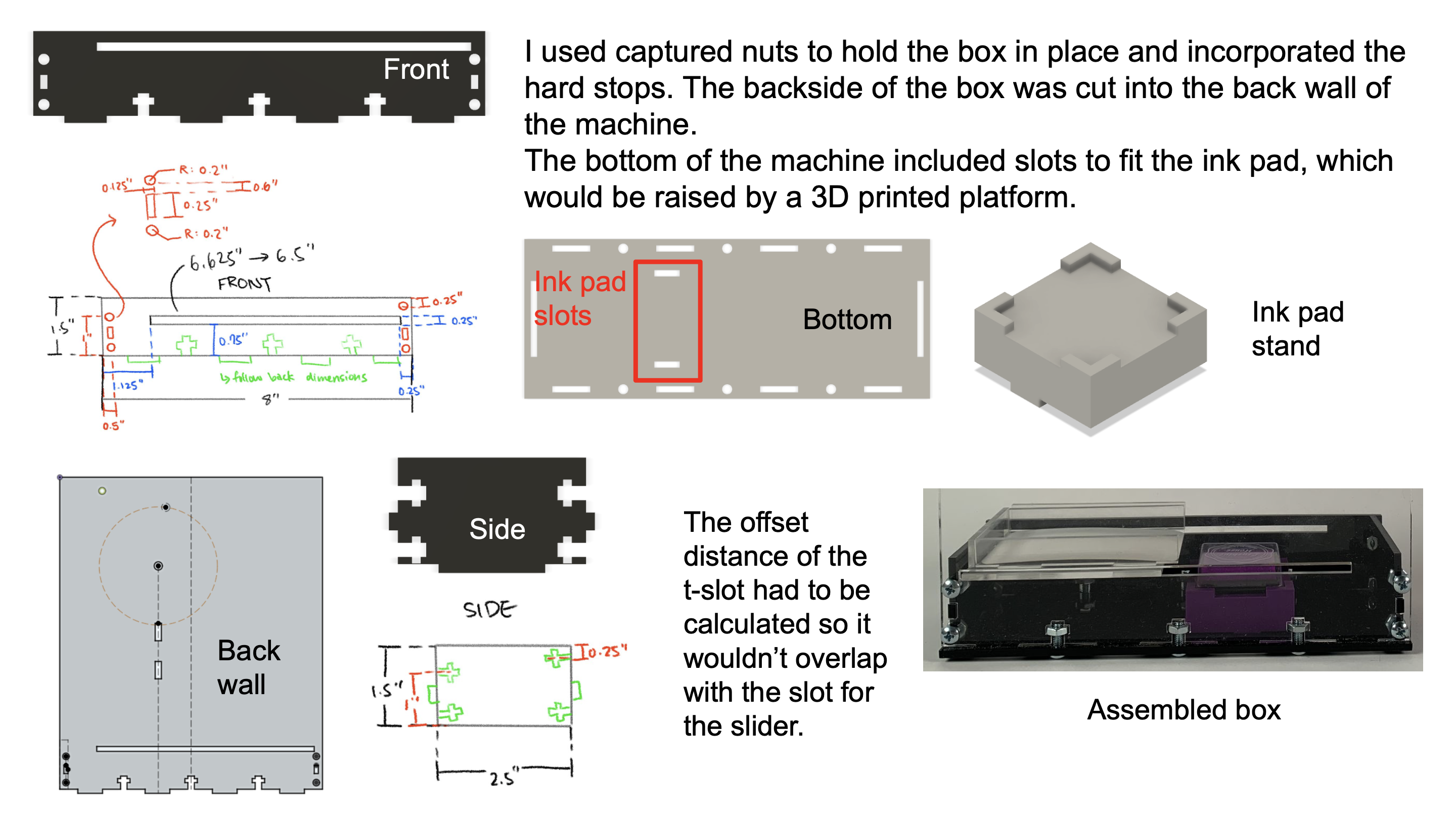

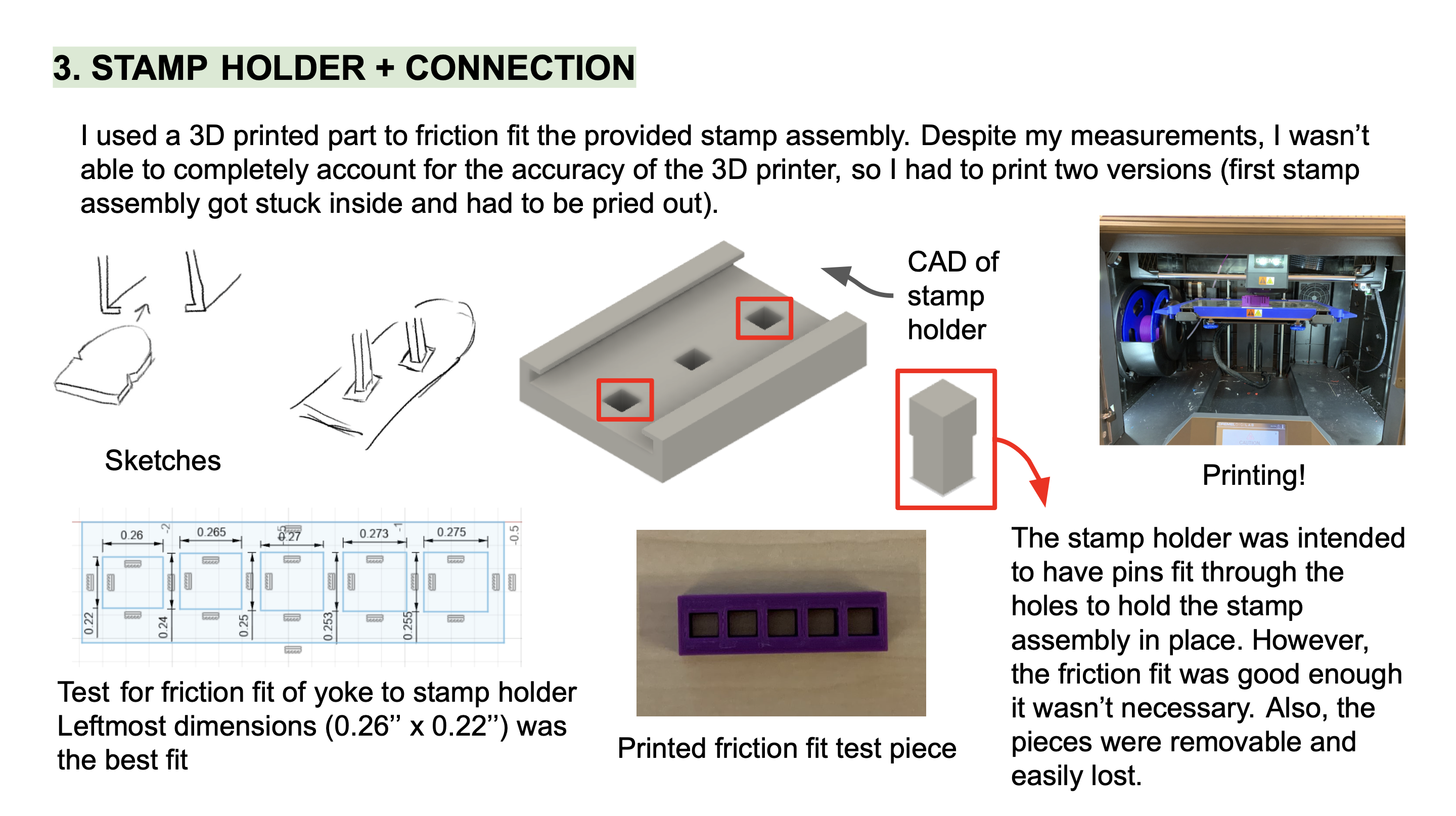

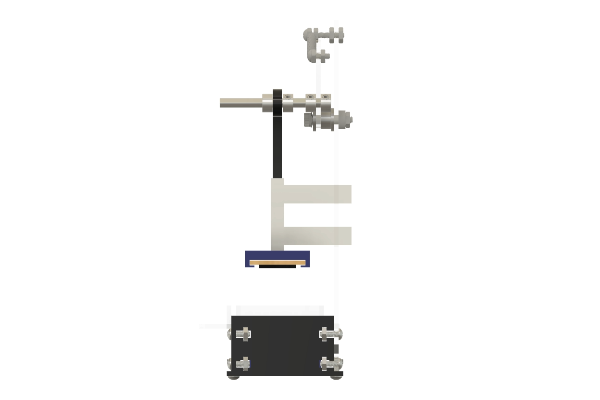

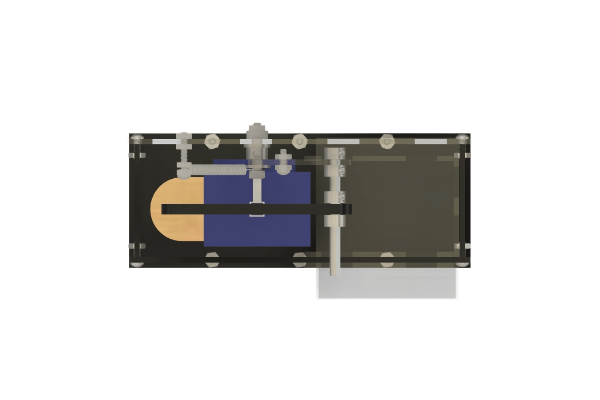

- I conducted analysis on different rotary mechanisms and identified the scotch yoke as the most space efficient in converting linear motion into rotation. Using rapid prototyping,

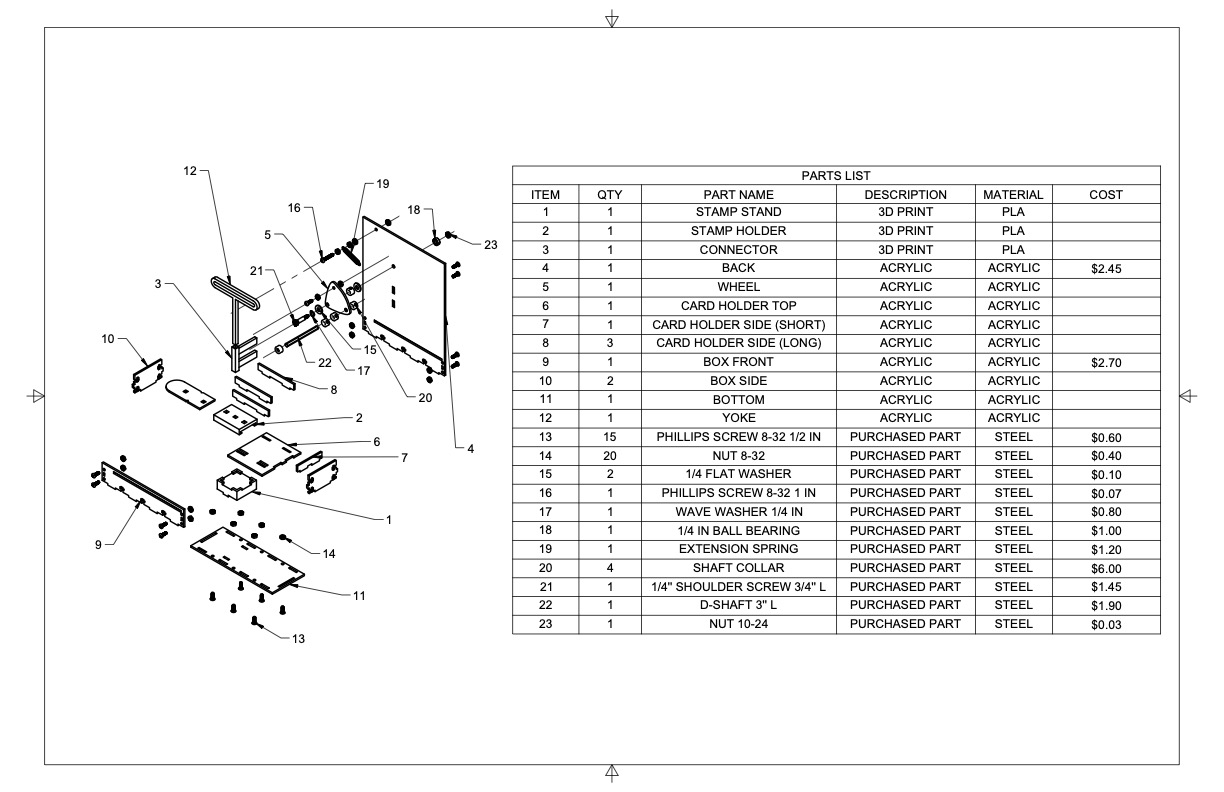

- I developed the device and created CAD assemblies to model the design and predicted motion.

Result

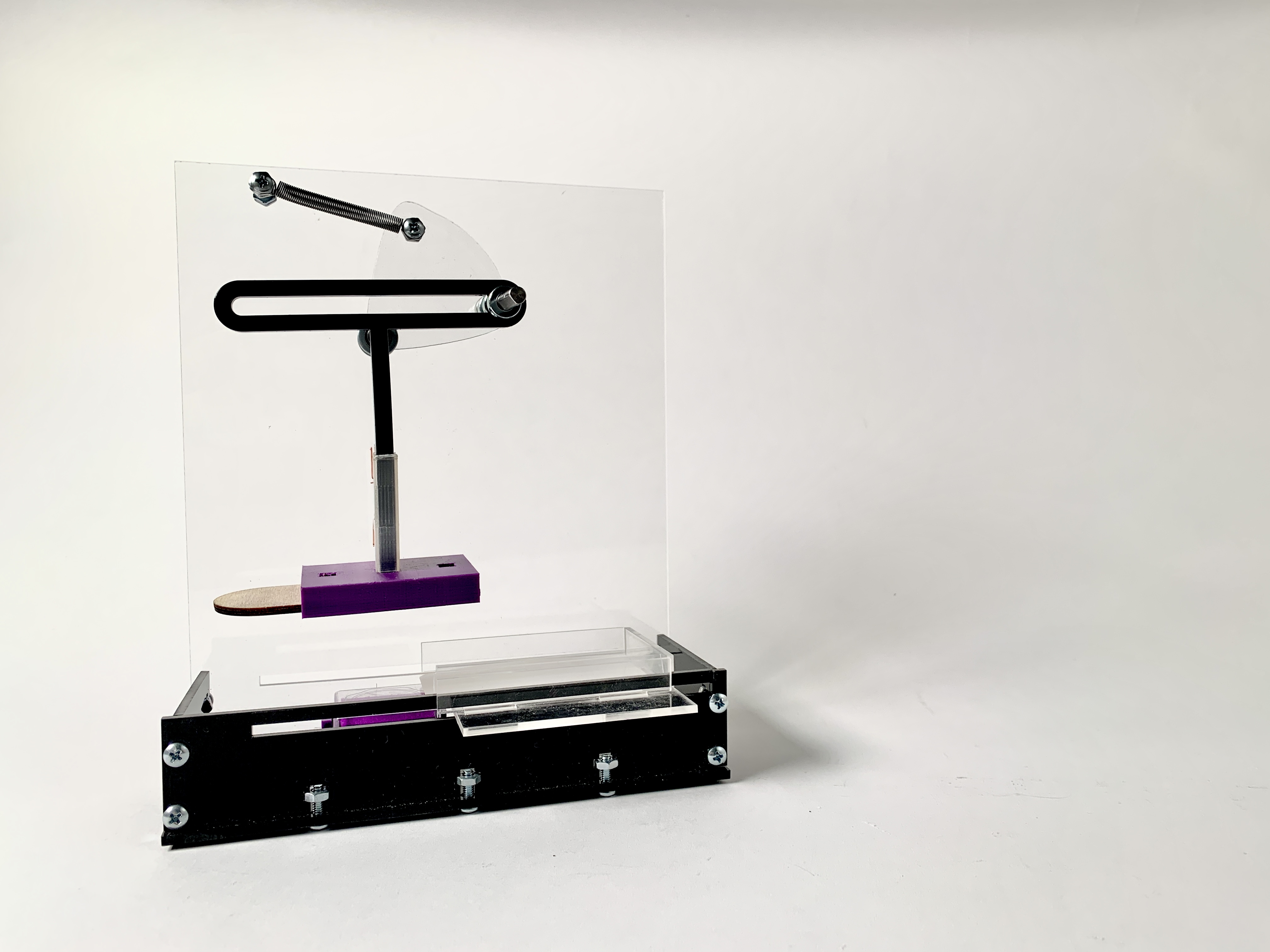

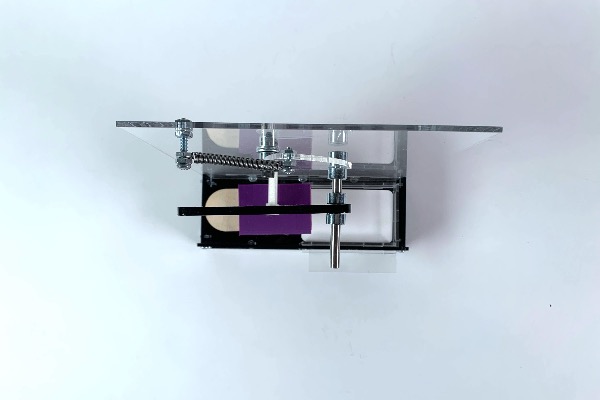

- I used 3D printing and laser cutting to create a fully functional stamping machine that can be actuated with one hand.

- I further developed my skills in prototyping and product realization through the integration of hardware and different materials.

- I gained skills on GD&T, building the bill of materials, creating exploded assemblies, and creating intuitive designs.

Real Final Model:

CAD Assembly:

Operation Instructions:

Bill of Materials: